Process control system

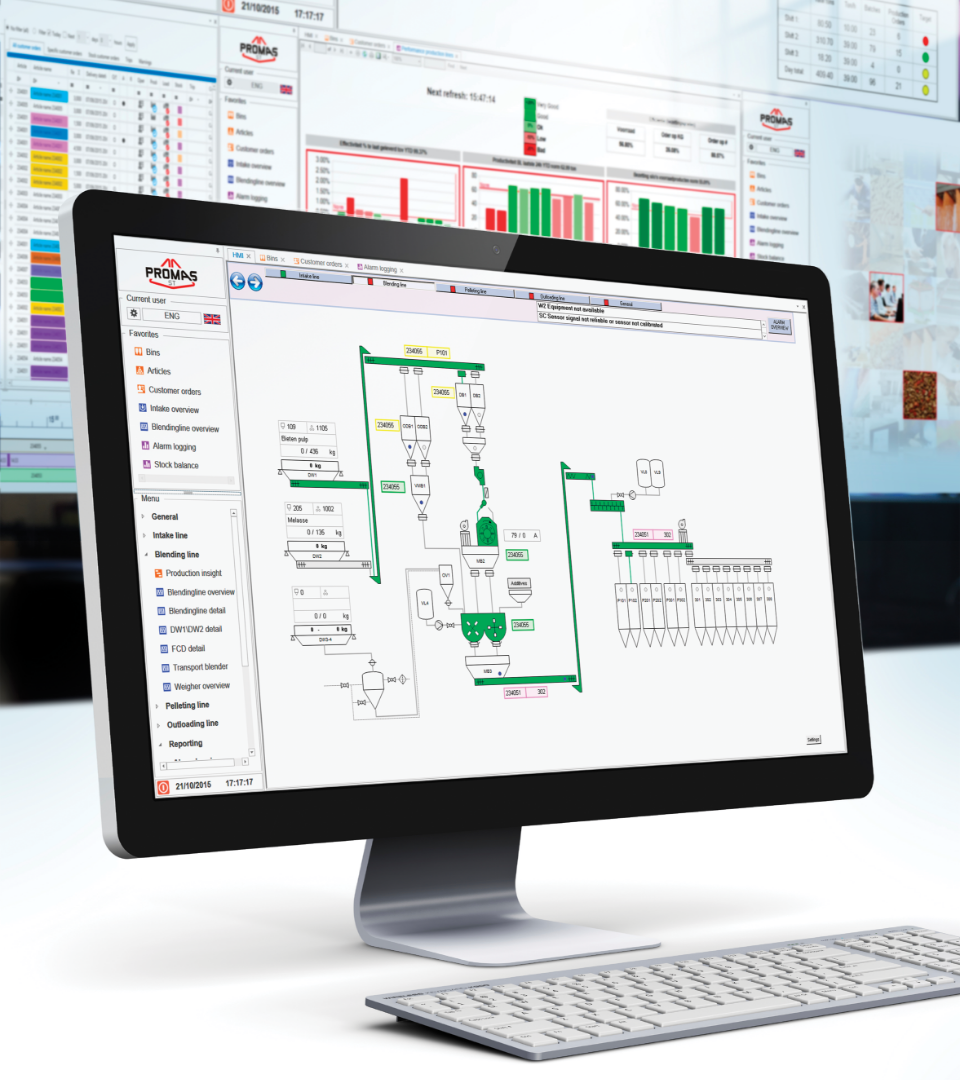

PROMAS ST Management Execution System (MES): achieving operational excellence

KSE’s PROMAS ST Management Execution System (MES) is an invaluable tool to ensure you know what’s happening, where it’s happening, and where to look to enhance performance. Our Management Execution System (MES), and Manufacturing Operations Management Software (MOMS), will help you optimize your production by improving capacity and quality and reducing costs. Choosing for KSE’s Management Execution System (MES) is a choice for the future. This Process Control System is future-proof and can withstand the test of time. The Process Control System grows as your company grows and new additions or changes to your production plant are easily integrated. There are many more benefits of KSE’s Management Execution System (MES):

- Complete functionality for incoming raw materials and outgoing finished products.

- Complete data management for controlling the production within our Process Control System.

- Production planning tool that provides a detailed and realtime insight into the expected end time for production and occupation of production lines.

- Comprehensive reporting tool that gives direct access to production information.

- The Manufacturing Operations Management Software contains a Track & Trace tool to stay in compliance with legislation and regulations for manufacturing.

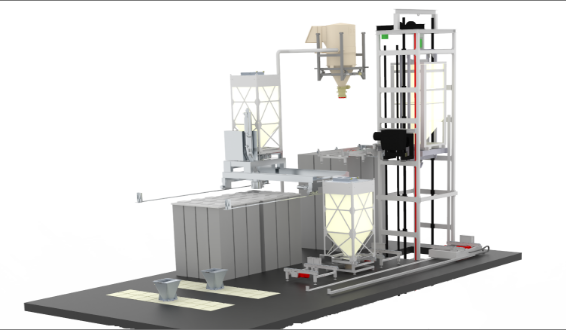

ALFRA ACT: a revolutionary, contamination-free container system for flexible transport

Do you want a container system that reduces contamination and increases your product safety in a flexible production unit? The solution is available in the ALFRA Container Transfer System (ACT). With the ALFRA ACT container system, it is possible to transfer ingredients with very little to even zero contamination.

Zero-contamination can be achieved by using dedicated containers for each product group. Preventing cross contamination with the ALFRA ACT container system improves the safety and quality of your product since ingredients that are essential to the diet of one animal can be a health risk to others. This allows you to safeguard your quality and build a reputation as a reliable manufacturer, all thanks to the ALFRA ACT.

The ALFRA ACT is extremely robust, fast, energy saving, dust-free and extremely flexible. To guarantee maximum product safety and quality, this container system is fully automatic and uses advanced techniques such as Tracking & Tracing, RFID coding and check-weighers. The ALFRA ACT container system operates with modules, meaning that this system can be adapted to suit your production plants exact needs. The Clean in Place (CIP) module of the ALFRA ACT container system efficiently and automatically cleans and disinfects the containers after each use to ensure that the highest standard of hygiene is maintained.

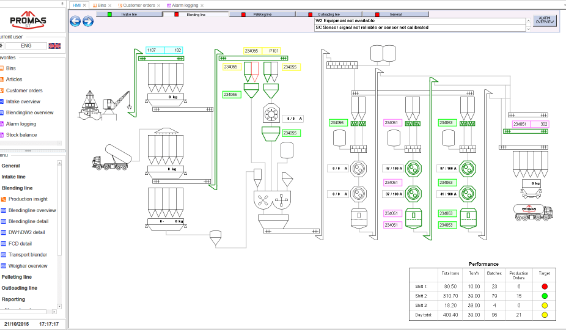

PROMAS ST Process Control System: enhance your plant operation

KSE’s factory automation software includes a Process Control System (PCS) for incoming raw materials and outgoing finished products. This system includes modules for every type of machine in your production process. All software modules are thoroughly tested in the field to ensure a robust and reliable system. This Manufacturing Operations Management Software enables complete control over your entire production process. The Process Control System is able to analyze data from your production and give insight into potential bottlenecks giving you a bird’s eye view that can aid you in improving the efficiency of the process.

The Process Control System ensures that your factory (including machines from third parties) performs as expected and in many cases, beyond your expectations. With the PROMAS ST Process Control System you can produce more tonnage with a higher quality. All performance indicators are visible in realtime wherever you are in the world. The return on investment is also better because PROMAS ST is both hardware and software independent. This means that you save costs when expanding or modifying your production line. In this industry with its ever changing recipes based on the newest science, it is important to remain flexible in your production approach. The PROMAS ST Process Control System offers this flexibility. Easily integrate new machinery and equipment into your plant and immediately see the return on your investment.

Six reasons why PROMAS ST is the Process Control System for your production plant

- The PROMAS ST Process Control System ensures flexibility allowing for growth in small companies and streamlining in large ones.

- Improve the capacity, quality and safety of your production while reducing costs.

- The Process Control System operates on an intuitive Windows platform.

- Enjoy the benefits of a modular and scalable approach from single machine control all the way to complete factory automation.

- Easily integrate and upgrade your hardware with the PROMAS ST Process Control System and stand the test of time.

- Never lose track of your products all the while preventing cross contamination.

Other interesting links: Automatic Bin Refilling | Plant Process Equipment | Mineral Process Equipment | Powder and Bulk Solids Equipment

Need personal advice?

Let us contact you.

Please leave your contact details below and we will get in touch.