A mutual webinar by KSE and Adisseo on how to improve effeciency when dosing even the smallest components.

How do we transport batches from any silo to any sacking line without contaminating or damaging the kibbles?

What is the right solution for loading trucks with different types of feed and how do you avoid carry-over and segregation of feed?

How do you transform your data into useful information for continuous improvement of your plant's throughput and product quality?

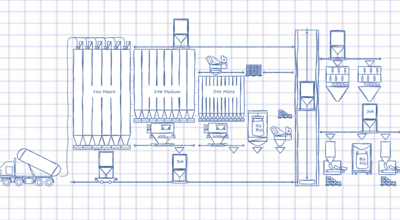

What is involved when building a new plant and what are the requirements when modifying an existing plant?

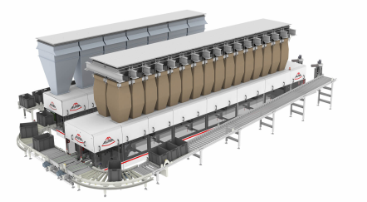

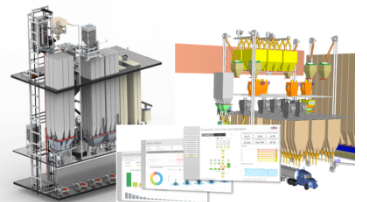

The ALFRA Box Dosing System (BDS) is a dosing installation that is designed to completely automate the preparation of micro ingredients for animal feed production in boxes. Manual preparations of ingredients are often time-inefficient, cause production delays, are prone to human error and involve health & safety risks.

The feed industry must deal with lots of challenges. More and more animal specific recipes must be made with minimum contamination. This requires a highly flexible production, with high efficiency and easing operator interference.